1 ~ 200L Rubber (Plastic) Dispersion Kneader (Kneading Mixer, Mixing Machine)

The rubber (plastic) dispersion mixer (kneader) is mainly used for rubber or plastics mixing and plasticizing, or rubber and plastic blending. It is a type of economical, energy-saving and environmental friendly mixing equipment that widely used in the field of rubber and plastic product industries.

Key:

Category:

Product Description

Application of Dispersion Kneader

The rubber (plastic) dispersion mixer (kneader) is mainly used for rubber or plastics mixing and plasticizing, or rubber and plastic blending. It is a type of economical, energy-saving and environmental friendly mixing equipment that widely used in the field of rubber and plastic product industries.

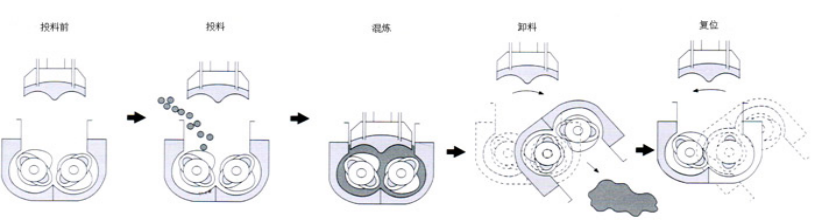

Work Process of Dispersion Kneader

Features of Aoqian General Dispersion Kneader

1. Rubber or plastic stock can be plasticized or mixed in a closed and pressurized space with the temperature controlled so that the productivity is high and the quality is good and stable.

2. Optimization of the parameters such as the helical angle of rotor wings and the wing overlap length brings about even distribution of the stock.

3. All the parts in contact with stock are ground, plated with hard chrome and polished. The rotor wings are built up by welding with the abrasion-proof sintered carbide to resist abrasion and corrosion.

4. All the parts in contact with stock are of the jacket design where water/steam/medium oil is led through to provide cooling or heating and can meet different requirements for the rubber or plastic mixing process.

5. Stock is fed through the rear door of the framework (or another port) and discharged by tilting the mixing chamber forward by 140°. Such a design makes it possible to arrange the up and down process in a line and facilitates stock color changing and the mixing chamber cleaning.

6. The standard tilting system of 75L~200L dispersion mixer adopts hydraulic driving, which is more stable and efficient. Worm and gear tilting system is adopted for 1L~55L models. It is optional according to customers’different requirements.

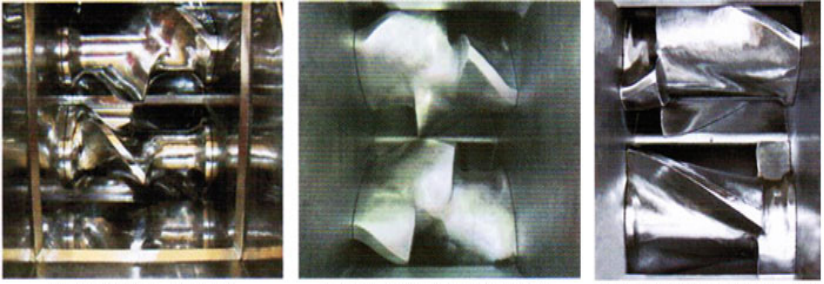

7. Besides standard Two-wing rotor, two more types are optional to meet customers’production requirement.

Product Inquiry